How to Set the Timing on an Accucraft Ruby: A Comprehensive Guide

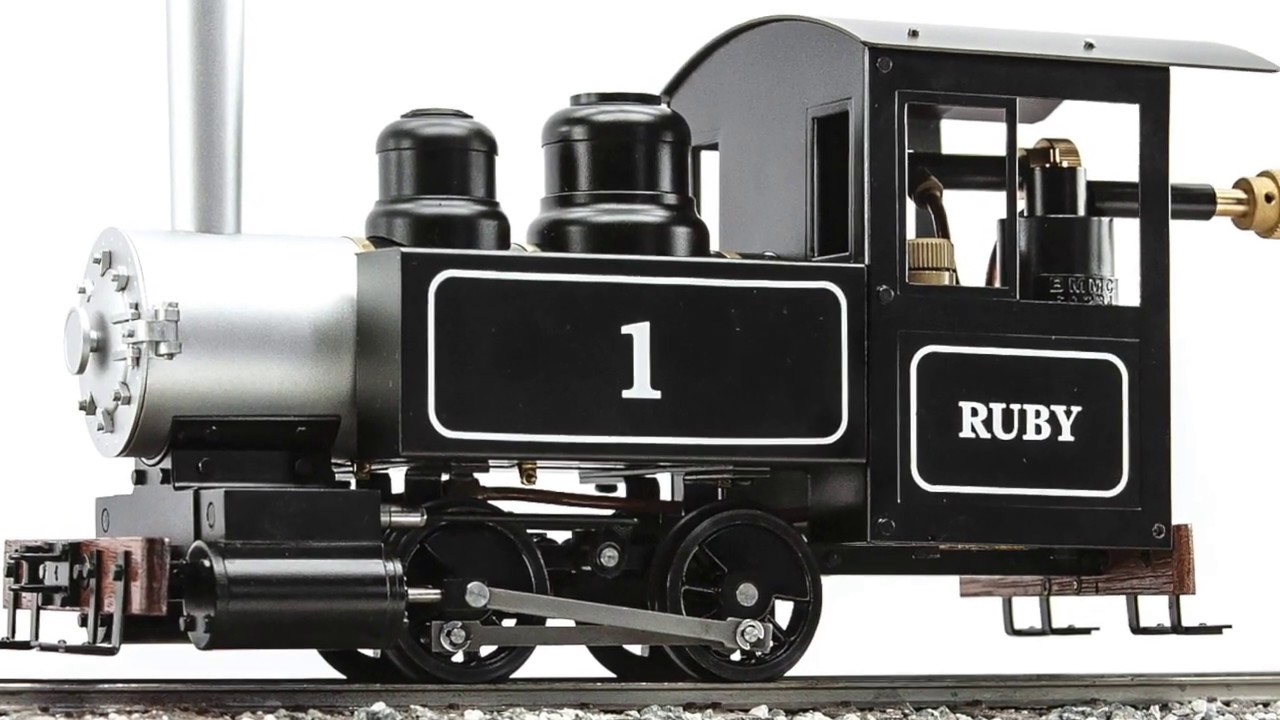

How to Set the Timing on an Accucraft Ruby: The Accucraft Ruby is a beloved model of live steam locomotive known for its precision and craftsmanship. For enthusiasts and hobbyists, setting the timing on the Accucraft Ruby is a crucial task to ensure optimal performance and smooth operation. Proper timing adjusts the engine’s mechanics to achieve efficient steam use, reliable operation, and peak performance. This guide provides a detailed and unique approach to setting the timing on your Accucraft Ruby, covering the necessary tools, step-by-step instructions, and tips for fine-tuning.

Understanding Timing in Live Steam Engines

Timing in a live steam engine refers to the precise alignment of the valve gear, which controls the steam distribution to the cylinders. Proper timing ensures that steam is admitted and exhausted at the correct moments during the engine’s cycle, which is critical for efficient operation and preventing mechanical issues.

Key Components Involved

- Valve Gear: The mechanism that controls steam flow into and out of the cylinders.

- Cylinders: Where steam pressure drives the pistons to power the locomotive.

- Crankshaft: Converts the pistons’ reciprocating motion into rotary motion.

- Timing Marks: Reference points used to align the valve gear correctly.

Tools and Materials Needed

Before starting, gather the following tools and materials:

- Screwdrivers: Various sizes for removing and adjusting components.

- Timing Gauge: A precision instrument to measure and set valve timing.

- Lubricant: For smooth operation of moving parts.

- Hex Keys or Allen Wrenches: To adjust valve gear settings.

- Clock or Stopwatch: To measure timing accurately.

Step-by-Step Instructions for Setting Timing

1. Preparation

- Ensure Engine is Cool: Before working on the timing, make sure the locomotive is cool and depressurized.

- Remove the Boiler: Carefully detach the boiler from the chassis to access the valve gear and cylinders. Refer to your Ruby’s manual for specific instructions on this process.

2. Access the Valve Gear

- Locate the Valve Gear: Identify the valve gear mechanism, which is typically located beneath the cylinders.

- Remove the Cover: If necessary, remove any covers or panels to expose the valve gear and timing components.

3. Set Initial Timing

- Find the Timing Marks: Locate the timing marks on the crankshaft and valve gear. These marks are essential for aligning the valve gear correctly.

- Align the Marks: Rotate the crankshaft to align the timing marks with the valve gear. This initial alignment ensures that the valve gear is in the correct position for setting the timing.

4. Adjust Valve Gear

- Check Valve Position: With the timing marks aligned, check the position of the valve relative to the piston. The valve should be positioned to allow steam to enter and exit the cylinder at the correct points in the cycle.

- Adjust the Valve Gear: Use the hex keys or Allen wrenches to make fine adjustments to the valve gear. Ensure that the valve opens and closes at the right moments in relation to the piston’s motion.

5. Verify Timing

- Reassemble the Engine: Once adjustments are complete, reassemble the engine, ensuring all components are securely fastened.

- Perform a Test Run: Carefully steam the locomotive and observe its performance. Look for smooth operation, correct steam admission, and proper exhaust timing.

- Fine-Tune as Needed: If necessary, make further adjustments to the timing based on the test run. Repeat the process until the engine operates smoothly and efficiently.

Tips for Optimal Timing

- Refer to the Manual: Always consult the Accucraft Ruby’s manual for specific details on timing and adjustments.

- Work in a Well-Lit Area: Ensure your workspace is well-lit to clearly see and adjust the timing components.

- Take Your Time: Proper timing can be a meticulous process. Take your time to ensure all adjustments are accurate for the best performance.

- Keep Records: Document your adjustments and settings for future reference. This can be helpful for troubleshooting or making further modifications.

Troubleshooting Common Issues

1. Engine Stutters or Hesitates

- Check Timing Marks: Ensure the timing marks are correctly aligned.

- Inspect Valve Gear: Look for any binding or misalignment in the valve gear.

2. Excessive Steam Leakage

- Verify Valve Position: Ensure the valve is closing properly and not allowing excess steam to escape.

- Inspect Seals and Gaskets: Check for worn or damaged seals that might cause steam leaks.

3. Uneven Operation

- Adjust Valve Timing: Fine-tune the valve timing to ensure even steam distribution.

- Check Crankshaft Alignment: Ensure the crankshaft is properly aligned with the valve gear.

Conclusion

How to Set the Timing on an Accucraft Ruby: Setting the timing on your Accucraft Ruby is a vital skill for maintaining the locomotive’s performance and ensuring a smooth, enjoyable operation. By following the detailed steps outlined in this guide and utilizing the tips and troubleshooting advice, you can achieve precise timing adjustments that enhance your Ruby’s performance. Remember, patience and attention to detail are key to mastering this aspect of live steam engine maintenance. Happy steaming!